epoxy garage flooring

Stop and take a look at your garage floor. is it cluttered, ridiculously dirty, and stained?

One of the toughest and most durable finishes that you can apply to a garage floor today is an epoxy floor coating. Since most garages are quickly becoming more than just a place to park your car, an epoxy floor coating can instantly transform your garage floor from a dirty stained nightmare into an incredible aesthetic, clean floor with a showroom shine.

WHAT IS GARAGE FLOOR EPOXY?

We’ll start by ending some confusion about epoxy right now. An epoxy floor coating is not paint. Paint for garage floors is a latex acrylic product. Some paints will have a small percentage of epoxy added to the mix to make it more durable than standard paint, but it is still paint. These are known as epoxy paints or 1-part epoxy paint.

Epoxy coatings are based on a combination of resins and hardeners that are mixed prior to application. When mixed together, the resin and hardener chemically react to produce a hard, chemical and solvent resistant finish. It is the specific selection and combination of the epoxy component and the hardener component that determines the final characteristics and suitability of the epoxy coating for a given environment. Epoxy coatings are so strong that they’re often used in the most demanding environments such as industrial environments, hospitals, or sports facilities. Epoxy coatings resistance to high levels of wear and tear, making it the most long-lasting flooring options.

Epoxy Floor Coating Benefits!

- EASY TO CLEAN – an epoxy floor coating creates a seamless floor that is highly resistant to water and spills for easy cleaning.

- ANTI-SLIP SURFACE – additive can be added to to the epoxy to create a slip resistant surface.

- CHEMICAL AND OIL RESISTANT – our floors are specially formulated to withstand oil, gas, and many other chemicals.

- HIGH GLOSS SURFACE – the shine from your coating can help improve the brightness in your garage or workspace.

- WITHSTANDS HEAVY TRAFFIC – designed to withstand heavy vehicular traffic, rated for industrial use, don’t waste your money on a diy kit to only see it peel off when you back out of the garage.

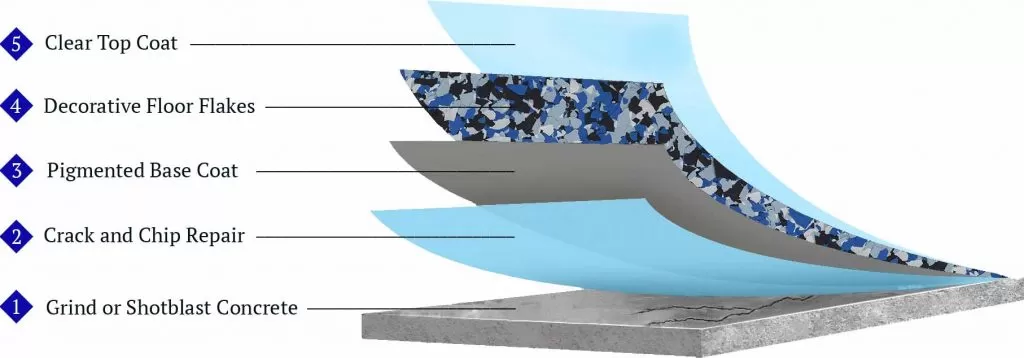

5-STEP PROCESS FOR A DURABLE EPOXY GARAGE FLOOR

Achieving a long-lasting epoxy garage floor is a 5 Step Process. It all begins with careful preparation of your existing concrete. This is the most important step for a successful installation. We begin by either diamond grinding or shot blasting your existing concrete to remove the cap of the concrete to provide us with a porous surface for the epoxy to sink into. Then any cracks or chip are filled with a fast setting polyurea filler or a polymer modified cement. The next step is to apply a pigmented 100% solid epoxy base coat. While the epoxy is still tacky we broadcast decorative flake chips to the floor until rejection. Once the base coat has dried we remove any excess flake and then apply a durable and chemical resistant top coat to keep you floor looking new and clean.

FAQ's

DO YOU PROVIDE FREE ESTIMATES?

Yes we do! During the estimating stage, it is a great time for us to find out your needs and present the best options to fulfill them.

What are the benefits of epoxy flooring?

Epoxy garage flooring is a versatile system that has many uses and benefits. While some people think epoxy is just used to produce a high-gloss finish, it can also add slip resistance, durability, chemical resistance, and a low-maintenance surface. Epoxy flooring combines aesthetics with durability and safety. It can be used in garages, inside houses, business, and patios. It’s a cost-effective way to transform a dusty, boring garage into a functional workshop or showroom that withstand vehicular traffic.

How Is the Floor Prepped Prior to the Epoxy?

Properly preparing your concrete slab for epoxy is the secret to a long-lasting and beautiful floor. How your floor needs to be prepped will depend on the condition of your concrete. Your concrete floor will first be grinned or shot blasted to remove the cap of the concrete and to get get rid of any containments. Any cracks or chips will be filled or repaired prior to applying an epoxy coating.

How Long Does an Epoxy Flooring Job Usually Take?

Most garage floors are completed in 1-2 days. After the last coat is applied the floor must be allowed to cure for 12 hrs before foot traffic. Vehicles and heavy objects should be kept off the floor for 72 hours. It takes about 7 days for epoxy to fully cure. During this time, avoid washing or scrubbing the floor.

When Wet, Is the Floor Slippery? Can I Avoid This?

One of the most common questions about epoxy is whether it creates a slippery surface. No one wants a garage floor that is so slippery it becomes a safety hazard. An epoxy floor with chips offers grip, but it will can still be slippery when wet. We recommend adding a skid-resistant additive to your epoxy before application. These granules, usually made from aluminum oxide, add traction.

Get a Free consultation and estimate today

Let's discuss your next decorative concrete project!

Contact Us Today

Follow Us

Contact Hours

M-F: 8am - 5pm

Sat-Sun: Closed